Non-destructive, magnetic-inductive localisation of the reinforcement was carried out using a mobile Ferroscan P250/200 system by Hilti. There are generally two options for measurement data logging:

- Logging of a linear measurement. For this method, a measuring path on the surface of the component is followed using a scanner. The reinforcing steel that is aligned perpendicular to the direction of travel is identified and the concrete cover and longitude is recorded.

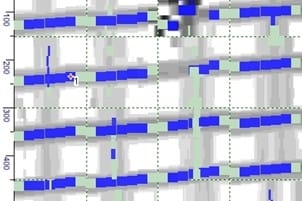

- Logging of a measuring surface. For this method, a measuring surface is scanned in perpendicular tracks. The measuring software uses the measurement data to calculate a graphic representation of the reinforcement in the concrete. Following the analysis, the concrete cover of the longitudinal and transverse reinforcement is identified.

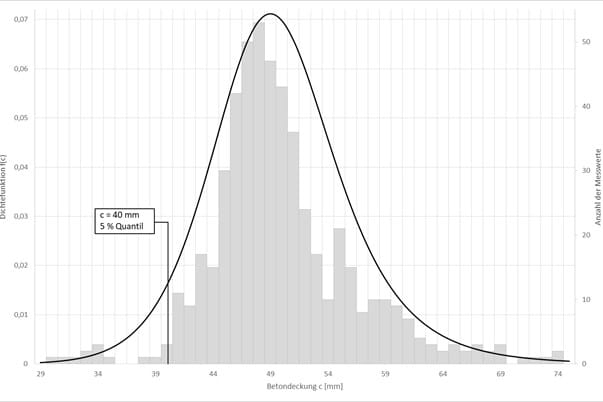

The size of the concrete cover and the rod intervals determine the quality of the measurement in particular. The recorded measurement data can be analysed according to the DBV information leaflet about concrete cover and reinforcement.

More projects

Determination of the fire resistance of a loaded laminated beech veneer lumber column

To investigate the behavior of prefabricated prestressed concrete floors (prestressed concrete…

Load testing in the context of converting the former Aktienspinnerei building in Chemnitz into the central library of the Chemnitz University of Technology

Experimental structural safety verification of historical cast iron columns in the old Chemnitz…

C³ – Carbon Concrete Composite

Our tasks included experimental verification concerning the creep behaviour in chemically reactive…